What is a hybrid rocket?

A hybrid rocket is a rocket engine system consisting of two different types of propellants, mainly solid fuel and liquid oxidizer, which are burned to produce thrust. Since the fuel and oxidizer do not mix spontaneously, there is no risk of explosion.

There are three mains advantages of hybrid rockets.

- High safety and low cost : Easy handling and management due to low explosion hazard

- High functionality in combustion control : easy combustion interruption and re-ignition, and thrust control by simply changing the amount of oxidizer supplied.

- Simple system: the only liquid is the oxidizer, and the structure is not as complex as a liquid rocket.

Conversely, there are three disadvantages of hybrid rockets

- Low combustion efficiency

- Low combustion regression rate

- Change in fuel/oxidizer mixing ratio (O/F)

A-SOFT (Alternating Swirl Oxidizer Flow Type) hybrid rocket

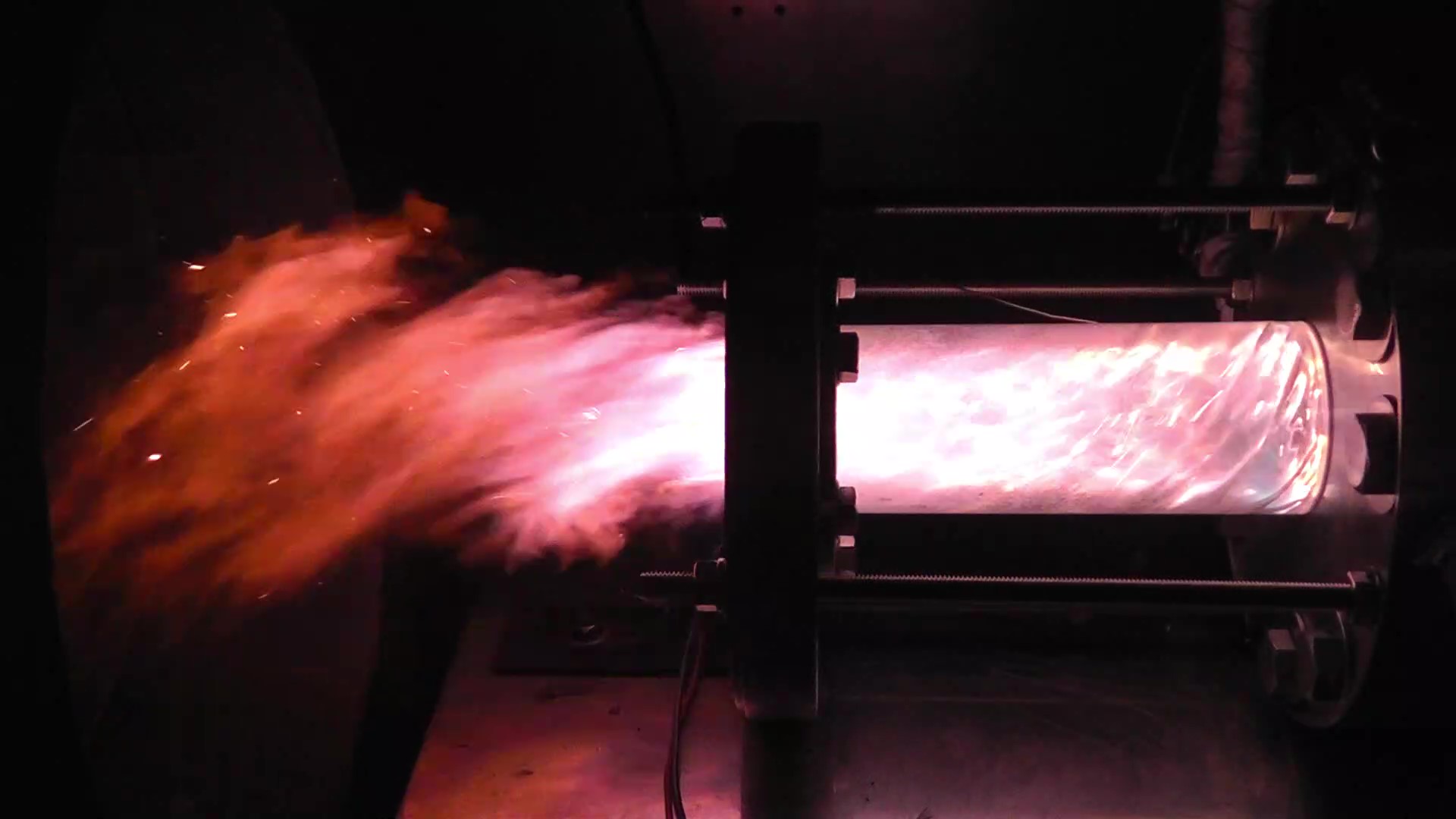

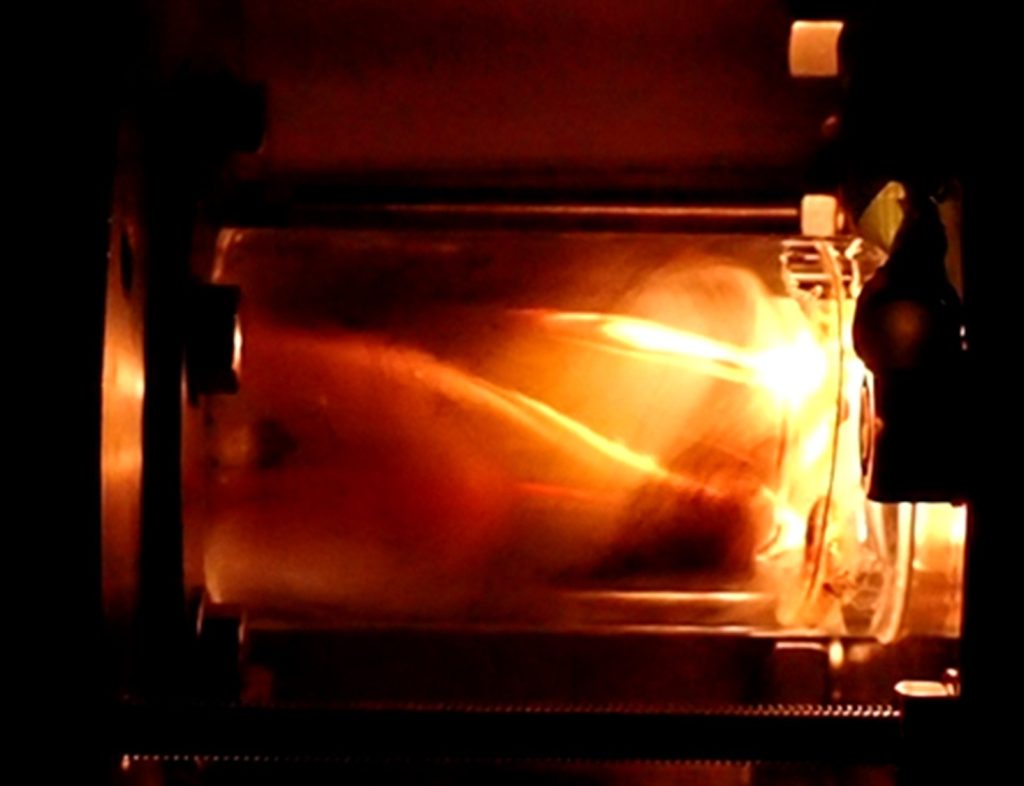

Photo Combustion of A-SOFT

A-SOFT is a system that solves the above shortcomings of hybrid rockets by providing two types of injectors, one for swirl flow and the other for axial flow, and independently controlling the flow rate.

The oxidizer is sprayed in a swirling stream, bringing the flame surface closer to the solid fuel and increasing the fuel recession velocity. Independent control of the two flow rates enables simultaneous control of the fuel/oxidizer mixing ratio (O/F) and thrust.

Basic research on A-SOFT hybrid rocket

[Experimental measurement of heat transfer characteristics of liquid oxygen]

In A-SOFT, achieving a high-intensity swirl flow requires using gaseous oxidizer rather than liquid oxidizer.

To do this while cooling the nozzle at the same time, a regenerative-cooling vaporization nozzle has been proposed, where liquid oxidizer flows along the nozzle wall, cooling it and vaporizing at the same time.

The cooling channel of this regenerative vaporizing nozzle must account for complex conditions such as small-diameter tubing, subcritical pressures, high heat flux, and two-phase flow.

Accurate prediction of heat transfer for oxygen undergoing phase change is essential, but there are no existing heat-transfer equations that can be applied reliably to these cooling-channel conditions.

Therefore, our laboratory aims to clarify the heat-transfer behavior of oxygen in these channels and establish a heat-transfer correlation that can be applied to the design of regenerative-cooling vaporization nozzles.

[Research and Developing of Hybrid Rocket Thrust Control System]

In hybrid rockets, the shape of the fuel grain changes during combustion. This causes the oxidizer-to-fuel ratio (O/F ratio) to change over time, making the combustion conditions unstable. A possible solution to this problem is to use two types of oxidizer flows, a swirling flow and an axial flow, and to stabilize the combustion by controlling each of these flows independently.

In our lab, we are conducting research with the aim of establishing the control process for these two flows and to verify it experimentally, and ultimately, to develop the flow-control technology required for the A-SOFT hybrid rocket.

[the effect of the injected oxidizer temperature on fuel regression rate]

In a “regenerative-cooling vaporization nozzle”, where the heat from combustion is used to vaporize liquid oxidizer flowing along the nozzle, the oxidizer temperature changes continuously.

Therefore, we are conducting research to determine how the fuel consumption rate per unit time, which directly affects rocket engine performance, varies with the temperature of the supplied oxidizer and the strength of the swirl flow. This fuel consumption rate is known as “the fuel regression rate.” In combustion experiments, after adjusting the temperature and flow rate of the injected oxidizer, we measure the fuel mass, and therefore, allowing us to determine the correlation between oxidizer temperature/flow rate and the fuel regression rate.

In the future, we will continue acquiring additional data under varied experimental conditions and work toward developing a predictive equation for fuel regression rate, advancing the realization of the regenerative-cooling vaporization nozzle.

[Hybrid Rocket Engine Ignition Research]

There are various ignition methods for hybrid rockets, such as pyrotechnics or spark ignition. Our lab uses Nichrome wire ignition. Using pyrotechnics undermines hybrid rockets’ major advantage of being “inherently non-explosive”, and therefore, Nichrome wire is considered more suitable.

For attaching the wire to the fuel, we use epoxy resin, which itself acts as a fuel.

Nichrome ignition process:

- The Nichrome wire is electrically heated to vaporize and ignite the fuel.

- The resulting flame is expanded using gaseous oxygen for ignition use.

- More gaseous oxygen for combustion use is then introduced to start full combustion.

An issue we are facing now is that increasing the flow rate of gaseous oxygen for combustion use sometimes extinguishes the flame before a sustained combustion can begin.

To solve this, we are currently studying the flame expansion pattern before oxygen is introduced and identifying conditions for reliable ignition.